Product Desgin

Sino Mold Product Design

Product design is a very important process in mold manufacturing. Good product design can not only save mold manufacturing costs and shorten the delivery time but also enhance the product’s aesthetics and satisfy your diversified product functionality needs.

For this reason, Sino-Mold is equipped with designers with more than 20 years of experience in mold making. 5 of our designers are fluent in English, and we will understand your requirements thoroughly before designing the product. Our designers will confirm the product details with you through Zoom if necessary. Whether your product is a consumer product, a medical device, or an industrial product, you can get a satisfactory product mold with the help of our designers.

Contact us today to speak with our team of designers about the details of your project.

Sino-Mold Product Design Work Flow

Step 01

Product define& Project Plan

After receiving your inquriy, our experienced designers will communicate with you in-depth to confirm every project specification to help our molds meet your needs.

Step 02

DFM Report

We will evaluate the mold’s material, precision, shape, and overall cost at this stage. This will help you make a better decision

Step 03

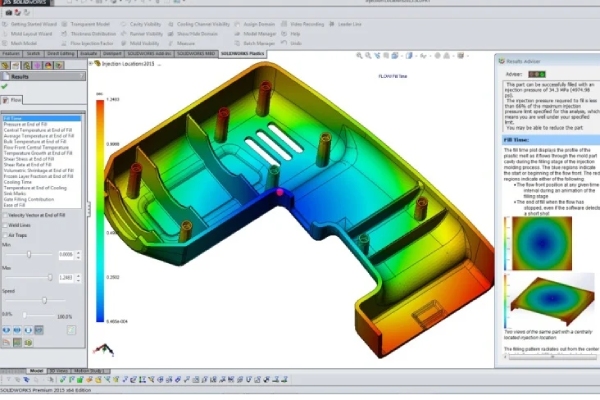

3D Modeling

We will use CAD software for 3D simulation and testing of mold manufacturing to help us avoid risks in the actual production process and complete your mold project more efficiently.

Step 04

Customer Approve of Mould Design & Mold Production

After completing the 3D Modeling, we will confirm all the details with you, and then your mold will enter the production and assembly stage.

Step 05

Mould Trial & Sample Inspection

After the mold production is completed, we will make a trial sample of the injection mold and send you 5-10 finished products so that you can evaluate the quality of the molds

Step 06

Customer Approve of Sample & Shipping

After you confirm that the sample meets your requirements, we will arrange the shipment of the molds, usually you will receive your molds within 7-10 days.

What Product We Designed ?

Sino-Mold provides high-precision mold production services for the automotive, pharmaceutical, industrial robotics, electronics, and consumer goods industries. Based on 20 years of experience in mold production and an annual capacity of nearly 500 sets of molds, whether you need plastic injection molding for mass production, over-molding for high functionality, or Silicon Molding for economic and practical use, you can find the right solution with us.

- Automotive Parts

- Medical Devices

- Electric & Electrical

Why Choose Sino-Mold ?

Sino-Mold provides professional, cost-saving, and ISO9001:2005-certified high-quality molds for you. We also offer one-stop service from design to assembly, 24hx7 engineers’ support, and more. To choose Sino-Mold, you only need to place an order, and we’ll take care of the rest.

25 Year Experience

Benefit from our 20+ years of experience, ensuring reliable, high-quality production with advanced equipment and a skilled professional team.

ISO 9001:2015 Certified

Our operations are ISO 9001:2015 and ISO 14001 certified, demonstrating our commitment to quality management and environmental responsibility in all our processes.

One-Stop Solutions

Streamline your product journey with our one-stop solution, integrating design to production for seamless project management, cost-efficiency, and faster turnaround under one roof.

Dedicated Team

Work with our skilled, English-certified engineers and workers who ensure clear communication and expert guidance throughout the manufacturing process.

Lightning Fast Delivery

Rely on our commitment to lightning-fast delivery between 7-10 days, ensuring that your urgent and planned needs are met efficiently.

24hx 7 Engineer Support

Round-the-clock assistance with our 24×7 engineer support, ensuring immediate expert help for any issues or inquiries to keep your operations running smoothly.

We Trusted BY

Frequently Asked Questions

Yes, we do. We have over 15 years of experience exporting molds, with more than 70% of our molds shipped internationally.

We can manufacture between 50 to 60 sets monthly, depending on the size and complexity of the molds.

We have approximately 100 employees.

We can handle molds up to a maximum weight of 15 tons.

About 30% of our molds are for the automotive sector. We have produced molds for major brands like Tesla, Volkswagen, Honda, Ford, Toyota, and Lamborghini.

Yes, we specialize in precision molds with mold tolerances of +/-0.05 to 0.01mm and product tolerances of +/-0.02mm.

Yes, we specialize in precision molds with mold tolerances of +/-0.05 to 0.01mm and product tolerances of +/-0.02mm.

We only use high-quality raw materials such as P20, P20H, 718H, NAK80, 1.2311, 1.2378, 1.2344, 1.2343 ESR, 1.2767, H13, 8407, 420SS, S136, S-7, etc., sourced from renowned suppliers like LKM and ASSAB. If specified, we provide a steel certificate and a heat-treatment certificate with the molds upon delivery.

The choice of hot-runner systems is determined by our customers. We partner with well-known suppliers such as INCOE, YUDO, DME, Mold-Masters, HASCO, Synventive, and Husky.

We prefer 2D and 3D part files along with mold specifications for quotations. We primarily utilize software like UG, AutoCAD, SolidWorks, and Pro-E. For 2D, we accept JPEG, PDF, DWG, and DXF formats. For 3D, we accept PRT, SAT, IGES, STEP, X_T, SLDASM, SLDPRT, and CATPart formats.

The standard lead time is about 4 weeks, although this can vary from 3 to 8 weeks depending on the mold’s size and complexity.