What Is Insert Molding?Benefits, Applications, and How It Works

Insert molding is more than just a plastic injection molding technique — it’s a reliable solution for producing strong, functional, and ergonomic components by combining metal or other rigid inserts with molded plastic.

Whether you’re working on automotive components, medical devices, or wearable electronics, insert molding helps streamline assembly, reduce part count, and enhance performance.

🔧 What Is Insert Molding?

Insert molding is a process where a preformed part (often metal, ceramic, or another rigid material) is placed into the mold, and molten plastic is injected around it to form a single, integrated component.

It’s commonly used for:

Embedding threads, shafts, or terminals

Reinforcing parts with metal cores

Combining soft-touch materials with rigid bases

🔍 Key Benefits of Insert Molding

✅ Improved part strength: Metal or composite inserts offer structural support

✅ Reduced assembly time: Combines parts into one molded unit

✅ Design flexibility: Supports compact, ergonomic designs

✅ Better durability: Enhanced wear resistance and reliability

✅ Cost savings: Fewer secondary operations and less manual labor

🛠️ Typical Applications of Insert Molding

Insert molding is widely used across industries:

🚗 Automotive

Dashboards

Door handles

Car’s key

Battery enclosures

📱 Consumer Electronics

Electronics components

Mobile device housings

🏥 Medical Devices

Diagnostic instruments

Surgical device handles

⚙️ Industrial Components

Gears

Pump housings

Control levers

⌚ Wearables

Watch enclosures

Sensor brackets

Soft-touch external frames

And so on.

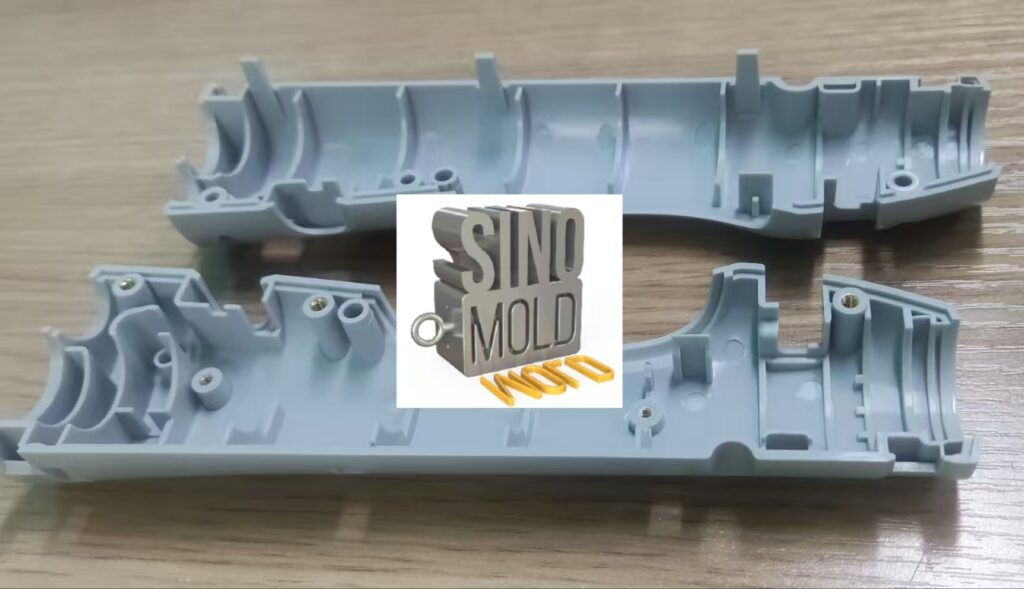

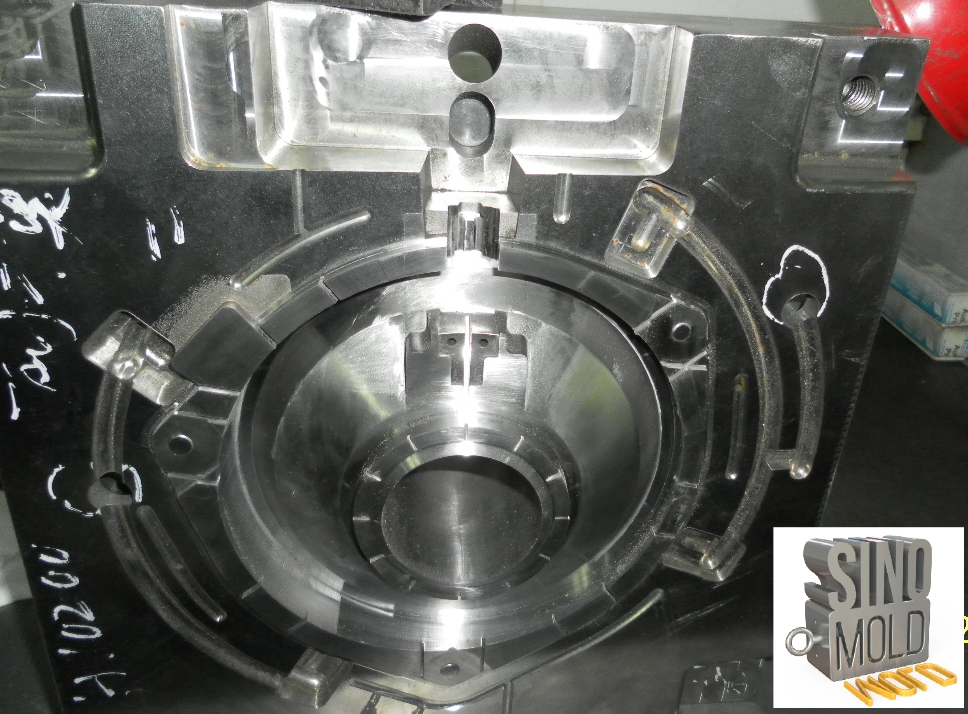

Insert mold for various plastic+metal parts

👨🏭 Our Capabilities

As a small to mid-sized tooling and molding shop, we offer highly customized, flexible support that larger factories may not:

🔹 20+ years of moldmaking experience

🔹 Design for Manufacturing (DFM) support

🔹 High-precision tool design and machining

🔹 Insert molding trials & small-volume production

🔹 Full-process support from prototype to production

We are not just moldmakers — we’re solution partners.

📌 Real-World Insert Molding Projects

Many of our projects involve tight tolerances, precision fit, and careful material compatibility — whether it’s the inner core of a personal care device or structural parts of wearable electronics.

This level of detail isn’t luck. It’s the result of:

Tooling and DFM

Meticulous tooling design

Stable molding processes

Close collaboration between engineers and operators

🤝 Let’s Talk About Your Next Insert Molding Project

If you’re developing a part that requires insert molding or overmolding, our experienced team is ready to support you — from early DFM feedback to small-scale production runs till mass production. We are here always for you.

📩 Contact us sales@sino-mold.com today to learn how we can assist with your tooling and injection molding needs.