Bringing Everyday Products to Life with Advanced Injection Molding

Injection molding is revolutionizing the consumer goods industry by enabling the production of highly durable, aesthetically pleasing, and intricately designed products. Our state-of-the-art injection molding processes empower brands to bring innovative and reliable products to market, from household items to personal care essentials

Consumer Goods Injection Molding Solutions

We deliver high-quality injection molded products that cater to a diverse array of consumer needs. Our portfolio includes innovative and reliable solutions for household items, recreational goods, and personal care products, ensuring each item combines functionality, aesthetic appeal, and long-lasting durability to meet the rigorous demands of daily use

- Home Appliances: Durable components that combine functionality with elegant designs.

- Children’s Toys: Safe, colorful, and robust toys that spark joy and creativity.

- Personal Care Products: Precision-crafted casings for beauty and health products that enhance user experience.

- Kitchenware: Food-safe, aesthetically pleasing, and highly functional kitchen tools and containers. Each product reflects our commitment to quality, safety, and customer satisfaction, designed to enhance everyday living.”

Why Choose Sino-Mold ?

Get Instant Quote

Email us and Upload Your Design. Our Expertise Experts Will Conduct a Manufacturing Feasibility Analysis of Your Parts and Provide Suggestions to Improve Efficiency and Save you Time and Cost.

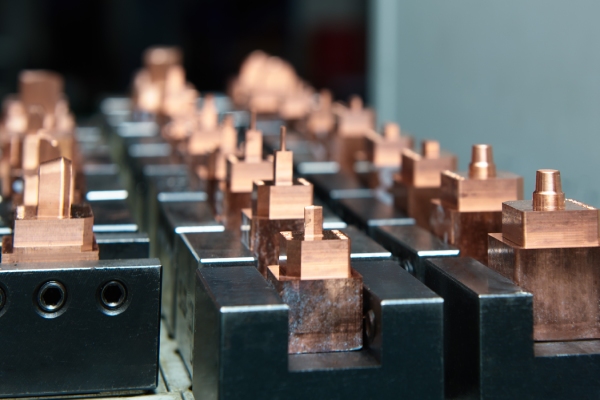

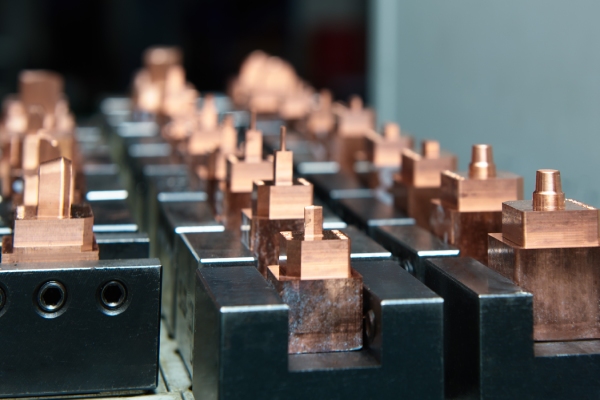

Strong Capabilities

Sino-Mold and Our Partner Offer almost every Part that you can think of, from Simple Cylindrical Geometries parts to Complex Shape Consumer Electrical Parts. You can always get what you want.

Fast Delivery

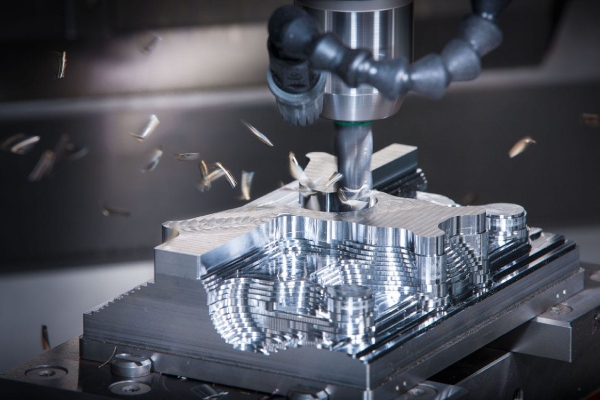

Lead time From 4 weeks. Sino-Mold can strictly Control the lead time by Combining our high-speed and precision CNC turning and milling centers with our Experienced Experts.

Qualtiy Assurance

As an ISO-certified company, we apply this standard to our production line for quality control. Sino-Mold Can also Provide First Article Inspection Reports, Full-Size Inspection Reports, and Material Certificates to ensure you can get Qualified Components.

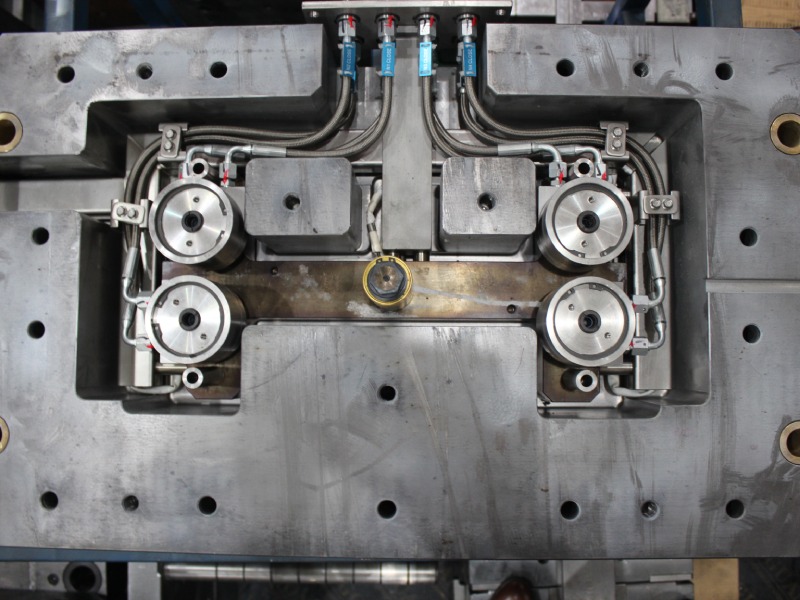

Automotive Mold Manufacturing Capabilities

Relying on SINO-Mold’s powerful production capabilities, we streamline the process of taking automotive parts from prototyping to mass production. This will help you get your parts into production quickly.