CNC Machining Service

Our factory and partners include almost every CNC Machining center on the market. We are proud to say that we can meet nearly all of your machining needs, from Straightforward to High-precision parts with Complex Geometries. We also offer services such as Wire EDM Machining, Minimum Feature Sizes, and Design Guide to help you get the right product.

CNC Turning

Our factory has a wide range of machines, including manual and high-precision CNC machines, to meet the diverse machining needs of our customers.

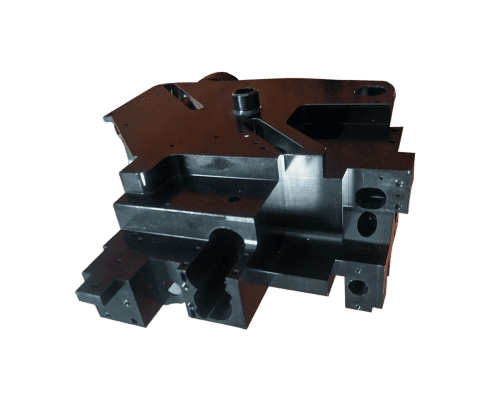

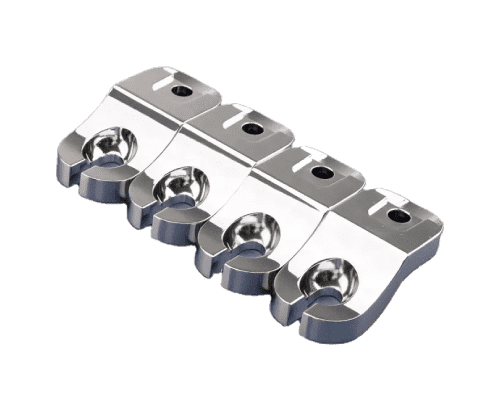

3 &4& 5 Axis CNC Milling

We offer 3, 4, and 5-axis CNC milling services. If your parts tolerances are beyond our capabilities. We can also help you achieve them easily through our partners and strictly control their production quality.

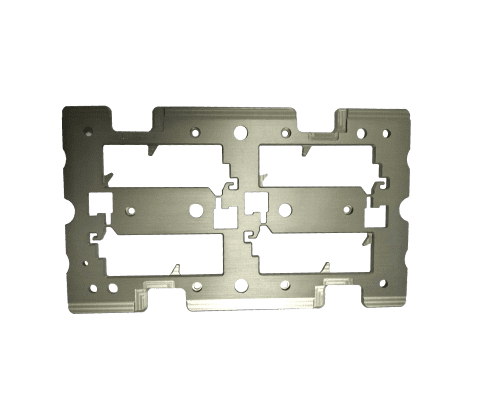

Wire EDM Machining

Wire EDM Machining is ideal for processing complex and intricate shapes, including sharp corners, narrow slots, and tight tolerances. It allows for high accuracy in cutting and shaping conductive materials.

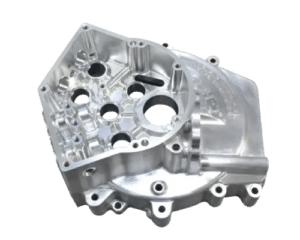

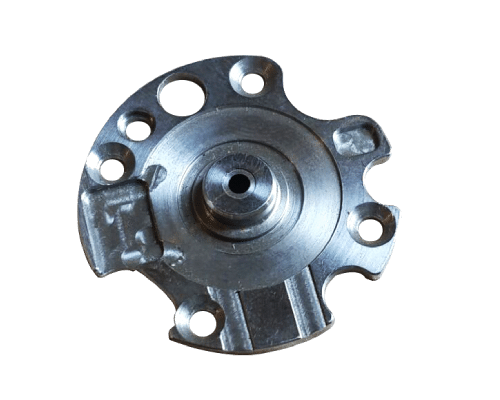

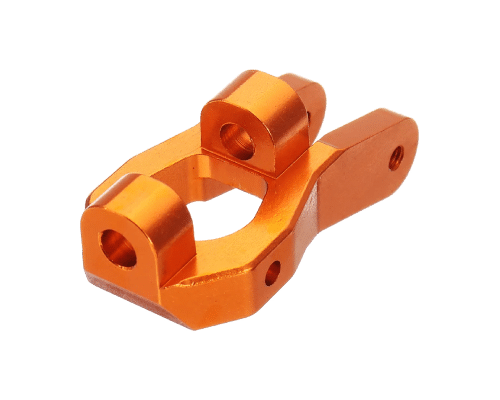

Gallary of CNC Machining Parts

STCNC can provide prototyping and Low-Volume Manufacturing services for aerospace, medical devices, consumer products, optical instruments, industrial automation, automotive parts, and more.

CNC Machining Materials

Sino-Mold Provides 50+ Metal and Plastic Materials for Custom Parts Manufacturing

CNC Machining Surface Finishes

Sino-Mold provides multiple finishes to suit your Special Needs.

As Machined

It is the Standard finish of our parts. The “As Machined “has a roughness of 3.2 micrometers (126 micro inches). We remove all sharp edges and burrs.

Anodize

Anodizing is an Electrochemical process that converts the metal surface into a Decorative, Durable, Corrosion-Resistant, Anodic Oxide finish.

Powder Coating

Powder Coating adds a thin layer to the Protective Polymer on the surface of the parts.it is a Strong Wear Resistance finish that is compatible with all metal. Custom color available.

Brushing

Sandpapers Brush parts with #400-600 grit, which result in a Unidirectional Satin, a finish mostly used for Aesthetic Purposes.

Bead Blasting

Part is Blasted with tiny Glass Beads using a pressurized air gun, which removes the machine marks and adds a uniform matte and textured on the parts.

Polishing

Parts are Polished in multiple directions by hand. The surface is Smooth and slightly reflective.it is suitable for appearance products—a bit higher cost.

Painting

They spray a Thin Layer of Paint on the surface parts, with Custom Colors available. You just need to provide the Panton Color number. Finishes range from matte to gloss to metallic.

Black Oxide

Black Oxide is one of the Conversion Coatings often used on steel. It can improve Corrosion Resistance performance and reduce light reflection.

Electroplating

It produces a Metal Coating on a solid substrate by reducing the Cations of that metal using a direct electric current.

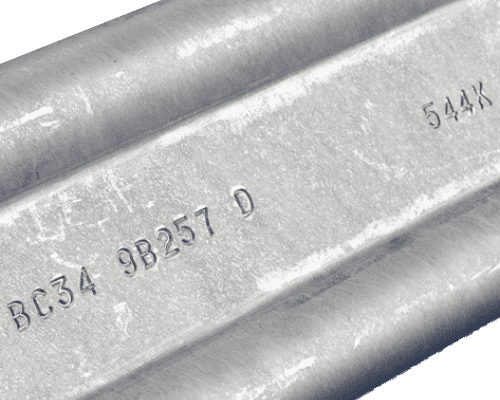

Part Marking

It’s one of the most cost-effective ways to add your Custom Logo or other contents to your parts, which is used in massive production. It’s highly efficient and saves more cost.

Sino-Mold-Consistent Quality Standard

STCNC offers all dimensions Striclty Quality Standards to Maximum your part’s quality.

Tolerance&Thread

Our factories strictly adhere to industry standards for threads and tolerances.

* ISO 2768 (m/f) for metal parts, 2768-m for plastic parts, ISO and ANSI/ASME for threads.

Cosmetic Standard

Cosmetic or No-Cosmetic, depending on Our Customer’s Actual Requirements. Usually include Surface Finishes &Visual Inspection.

Cleaning&Finishing

STCNC Machining Focuses on 3 Main Factors to ensure you can get ideal Parts, including Edge Breaking, Deburring, and Cleaning.

Inspection Standard

STCNC adheres to industry standard and ISO9001: 2015. We also have our Strictly inspection standard to ensure you can get Ideal Parts

Quality Reports

We provide quality documentation, such as First Article Inspection, Certificate of Conformance and Material Certificate on request.

Customer Database

After the first cooperation, we create your Personalized Database, which is essential in achieving Consistent Quality for your parts’ production in the future.

From Prototype to Production

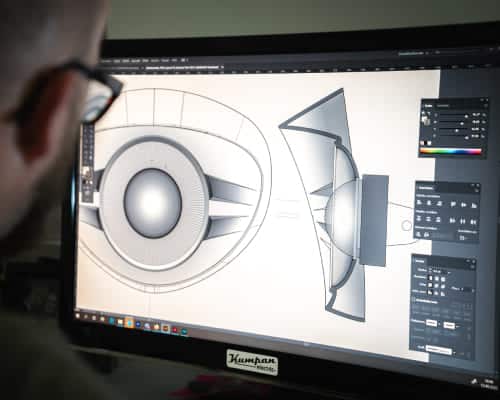

Rapid Prototype

We combined a Dedicated Engineering Team with advanced CNC and 3D Printing machines, which make customers’ ideas into reality through Rapid Prototyping.

- 3,4,5 Axis CNC Machining&3D Printing

- Expertise Designer&Engineers

- Lead time from 3 days

Accelerated your prototyping development cycles and Shortened your lead time. We know our equipment inside out, and our delivery commitment to you is always based on knowledge rather than an estimate.

Production

STCNC Machining and Our Partner can offer 100000 Pieces of Parts Every year. MOQ Lower to 1 Piece.

- Massive Production Capability

- Low Volume Manufacturing Solutions

- ISO Certificated Factories

STCNC provides small-batch CNC Machining and Large-Scale production services. Both Small Players and Large Companies can get their Satisfied Parts. (Inspection Report Available)

Frequently Asked Questions

Dedicated Team Work Make Greatness

CNC Milling Machining Operating

2D Projector Parts Inspection

Manually Milling Operating