Let’s talk about something that might seem small but carries a huge responsibility in packaging: plastic caps. These tiny heroes are the gatekeepers of product freshness, safety, and ease of use. Whether it’s the satisfying click of a flip-top cap on your lotion or the reassuring twist of a screw cap on a juice bottle, they’re doing more than just closing a container—they’re shaping the customer experience and protecting your brand.

If you’re a procurement engineer or project manager in the packaging game, you know that picking the right cap and mold isn’t a walk in the park. It’s about balancing practicality, cost, and that wow factor that makes a product stand out. In this guide, I’ll break down everything you need to know about plastic caps—the types, the materials, the molding magic, and where they fit in today’s industries. Plus, I’ll throw in a peek at what’s coming next. Ready? Let’s get started.

The Unsung Heroes of Packaging

Picture this: you’re at the store, eyeing a bottle of your favorite sauce. The cap’s gotta be easy to open, keep the contents safe, and maybe even look a little slick. A flimsy or faulty cap? That’s a dealbreaker. Plastic caps aren’t just functional—they’re a big part of what makes packaging work. They seal in quality, make life convenient for users, and give brands a chance to shine.

For folks like us in the industry, it’s all about nailing that sweet spot: a cap that performs like a champ and doesn’t break the bank. That’s where molds come into play. A top-notch mold ensures every cap is spot-on—consistent, sturdy, and ready to tackle whatever your product throws at it.

Types of Plastic Caps: What’s in Your Toolkit?

Caps come in all shapes and sizes, and each one’s got a job to do. Here’s the lowdown on the ones you’ll see most often:

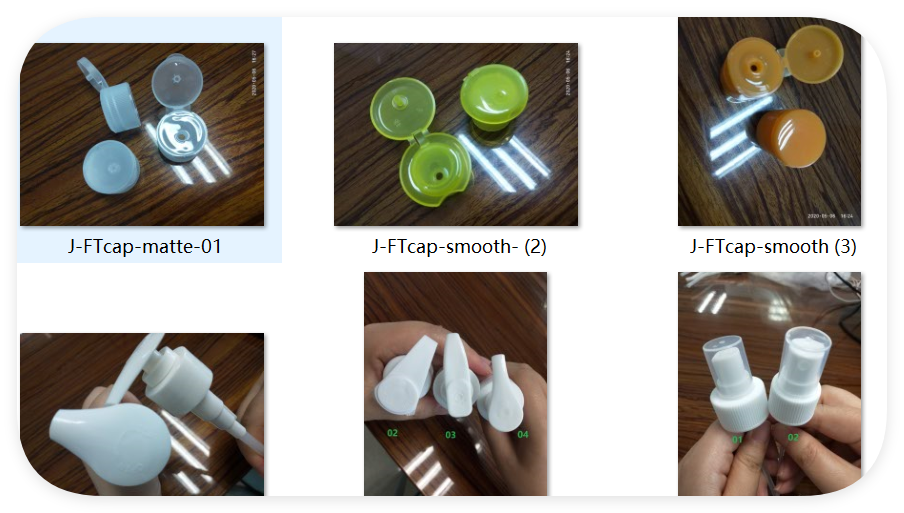

Flip-Top Caps

You know these from your shower routine—shampoo, body wash, or maybe a ketchup bottle. They’re all about one-handed convenience with that handy little hinge. Molds for flip-tops need to nail the flexibility and toughness of that hinge, which isn’t as simple as it sounds.

Screw Caps

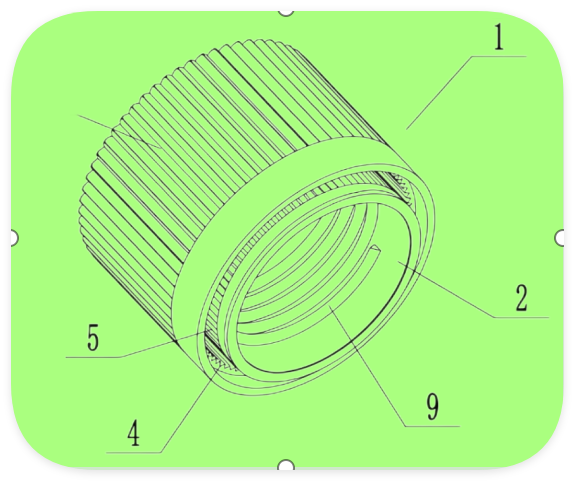

The classics. From soda bottles to pill containers, screw caps are everywhere because they lock in a tight seal with those trusty threads. The molds? They’ve got to be precise—any slip-up in the threading means leaks or stuck caps, and nobody wants that.

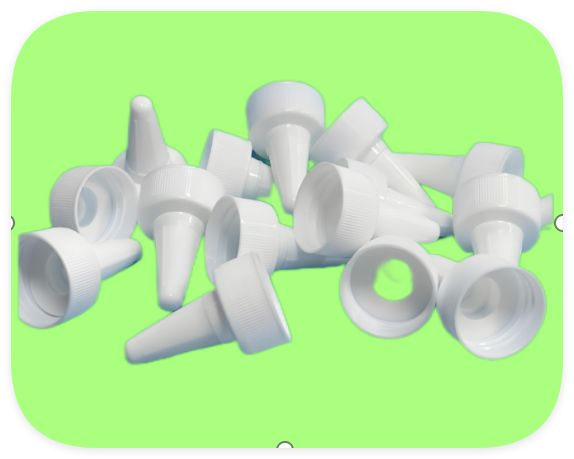

Dispensing Caps

Think disc-tops on lotion bottles or trigger sprayers for cleaners. These are built for control, letting just the right amount out. Their molds are a bit more complex, handling moving parts and funky shapes, but when done right, they’re a game-changer.

Child-Resistant Caps

Safety’s the name of the game here—think push-and-twist designs for meds or hazardous stuff. The molds have to meet tough standards, ensuring they’re kid-proof but still user-friendly for adults.

Tamper-Evident Caps

That little ring that snaps off when you open a bottle? It’s your proof the product’s untouched. Molds for these include delicate breakaway bits, and getting them perfect takes some serious skill.

Picking the right cap depends on what you’re packaging, who’s using it, and any rules you’ve got to follow. It’s like choosing the right tool for the job—except this tool’s got to look good too.

Materials and Making: What Goes Into a Great Cap?

A cap’s only as good as what it’s made of and how it’s crafted. Let’s dig into the essentials.

Materials That Make the Cut

Plastic caps usually start with thermoplastics—versatile, strong, and budget-friendly. Here’s what’s on the menu:

Polypropylene (PP): The go-to for food and personal care caps. It’s durable, shrugs off heat and chemicals, and works for both flip-tops and screw caps.

Polyethylene (PE): Comes in two flavors—HDPE for tough screw caps (like on milk jugs) and LDPE for softer, squeezable dispensing caps. It’s a champ at taking a beating.

Green Options: Everyone’s talking sustainability these days. Recycled plastics or biodegradable materials are stepping up, offering eco-friendly vibes that customers love.

It’s all about matching the material to your needs—durability, flexibility, cost, and maybe a little planet-saving cred.

Injection Molding: The Art of Cap Creation

When it comes to making plastic caps, injection molding is the rockstar. It’s fast, precise, and built for big runs. Here’s the play-by-play:

Designing the Mold: It starts with a custom mold tailored to your cap’s specs—simple or fancy, it’s got to be exact.

Melting and Injecting: Plastic gets heated up and shot into the mold under pressure, filling every corner perfectly.

Cooling and Popping Out: After it cools, the mold opens, and out comes the cap. For trickier designs like flip-tops, multi-shot molding might add hinges in one smooth move.

Checking the Work: Machines scan every cap to catch any duds—because a cap that doesn’t fit is a problem waiting to happen.

Injection molding’s a powerhouse for churning out caps that don’t just meet standards—they exceed them. With molds from experts like Sino-Mold, you’re looking at reliability that keeps your production humming.

Where Caps Rule: Real-World Uses

Plastic caps pop up everywhere, and each industry leans on them differently:

Food and Drinks: Screw caps keep soda fizzy; flip-tops make sauces a breeze.

Pharma: Child-resistant and tamper-evident caps keep meds safe and legit.

Beauty: Dispensing caps dish out creams, and cool finishes turn heads.

Home Goods: Trigger sprayers and push-pulls put you in charge of sprays and soaps.

The right cap, backed by a killer mold, keeps products top-notch and customers smiling, no matter the field.

What’s Hot: The Future of Plastic Caps

Packaging’s always on the move, and caps are keeping up. Here’s what’s trending:

Eco Vibes: Lighter designs and recycled materials are cutting waste and winning fans.

Smart Tech: Caps that track usage or freshness? Yup, sensors are making it happen, especially in pharma.

Standout Style: Brands are going bold with custom looks, pushing molds to be more creative than ever.

These shifts aren’t just flashy—they’re answering calls for greener, smarter, and slicker packaging. Staying in the loop here can set you apart.

Wrapping It Up: Molds Are the MVPs

For those of us steering the ship—procurement engineers and project managers—plastic caps are a big deal. They’re proof that great design and solid engineering can go hand in hand. Whether it’s a flip-top cap mold or a screw cap mold, it all boils down to precision. At Sino-Mold, we’re all about building molds that deliver—caps that fit, seal, and shine, every single time.

Want to up your packaging game? Swing by www.sino-mold.com and see how we can help you craft caps that get the job done—and then some. Email now :sales@sino-mold.com