Trusted Pipe Fitting Mold Manufacturer in China | Customized Molds for PVC, PP, PPR, PE

Looking for a reliable mold supplier for plastic pipe fittings? SINO-MOLD, based in China, is your trusted partner with over 20 years of hands-on experience. We design and manufacture tailor-made pipe fitting molds for PVC, PPR, PP, and PE materials—helping global clients achieve higher productivity and lower production costs.

Why Global Brands Choose SINO-MOLD.com

1. Engineered for Long-Term Performance

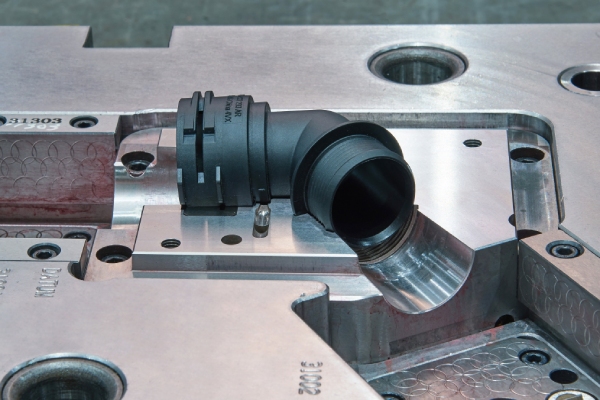

Many molds on the market cut costs by using angle lifters, but these mechanisms often lead to premature wear. At SINO-MOLD, If customer allow,we engineering molds using hydraulic core pulling systems for better balance, precision, and operational moldlife. Each slider can be treated with special coating to ensure smooth, low-friction movement—especially under demanding conditions.

2. Superior Steel and Double Tempering Process

The choice of steel and how it’s treated makes or breaks mold performance. We only use corrosion-resistant grades like H13,420, and your specify type. Each mold undergoes double tempering post heat-treatment to ensure a Rockwell hardness HRC meet your request, ideal for resisting the corrosive nature of PVC and extending mold life.

3. Fast Cooling = Shorter Cycle Time

Faster cooling directly increases output. Specify developed cooling system boosts water circulation efficiency by up to 30%, reducing cycle times while minimizing shrinkage and deformation. This is particularly critical for PP and PPR materials, which demand strict thermal management.

4. Full Range of Pipe Fitting Mold Solutions

We produce molds for a wide variety of applications:

CPVC fittings for hot and cold water systems

UPVC fittings for drainage and waste systems

PPR and PE fittings with collapsible cores for undercut geometries

Electrical conduit fittings, compliant with building standards

5. Zero Compromise on Quality

We implement strict quality control at every stage:

CNC & EDM machining with ±0.005mm tolerance

Mold trials using real polymer materials and cycle simulations

Transparent updates with 3D mold flow analysis, mold drawings,project progress update,tooling photos, and test videos and photos

Specialized in Solving PVC Molding Challenges

PVC presents unique molding challenges due to its low flowability, thermal instability, and aggressive chemistry.

SINO-MOLD addresses these with:

-

- Corrosion-resistant tool steel for longer mold life

-

- Balanced injection profiles to prevent material degradation

-

- Custom gate designs to reduce internal stress and avoid surface defects

- Global Service with Fast Turnaround

We wrok with clients across Europe,USA,South American,South African and so others.

Our capabilities include:

-

- 500+ molds delivered annually

-

- Lead times as short as 30–45 days

-

- Logistics flexibility with FOB, EXW, and DDP options

-

- 24/7 engineering support during mold design, production, and testing

Ready to Upgrade Your Pipe Fitting Production Mold?

Get in touch with SINO-MOLD today for a free mold quote consultation. We’ll help you fine-tune your mold for efficiency, durability, and with trusted after-service.

��� [Request a Quote] | ��� [Free DFM/Design Review Available]

Email now: sales@sino-mold.com

#plasticpipefittingmoldsupplierChina,#PVCPPRmoldmanufacturer,

#collapsiblecorepipefittingmold,#hydrulicpipemolddesign,

#custominjectionmoldforplumbingfittings,

#CPVCmoldhighpressure#moldmakinginChina#sinomoldinchina

#moldmanufacturerinchina#moldmakerindongguan