Factors to consider when outsourcing mold making to China

In today’s globalized business environment, outsourcing has become one of the important strategies for many enterprises to improve efficiency, reduce costs and focus on their core business. In the manufacturing industry, especially in the field of injection mold manufacturing, outsourcing has shown great potential and advantages. This article will discuss the many factors, that need to be considered when considering outsourcing mold manufacturing to China, Hope these views will help you to find a good mold/plastic injection supplier!

Trends of global outsourcing

Mold manufacturing of plastic products, as an important part of manufacturing industry, directly affects the production quality and cost-effectiveness of many products. Plastic injection molding plays a key role in the plastic injection molding process of plastics, and other materials, which determines the precision, appearance and performance of plastic products the final product. However, mold manufacturing and maintenance of plastic part usually require expensive equipment, professional technology and a large amount of manpower input, so many enterprises begin to consider outsourcing plastic mold manufacturing to reduce costs, improve production efficiency and maintain competitiveness.

In recent decads, the global mold manufacturing industry has shown a clear outsourcing trend in China. Many companies began to outsource the mold making process, manufacturing processes and raw materials to professional suppliers, so as to better focus on their core business, shorten the production cycle time, and gain technological advantages. This trend not only has advantages in cost, but also can use global resources to promote innovation and improve product quality.

What is the reason for choosing China as the outsourcing destination of mold manufacturing?

As one of the largest manufacturing countries in the world, China has large quantities of abundant labor resources, advanced manufacturing technology and rich manufacturing experience. All these factors make China an ideal destination for many companies seeking to outsource outsourcing injection molding and manufacturing.

Changan Town, Dongguan, as a famous mold manufacturing town in China and even in the world, has a complete range of supporting services for the whole industry, from mold steel, mold rough machining, mold blank customization, mold finishing, mold wire cutting, mold EDM, mold surface treatment etc., there are corresponding manufacturers to provide supporting services, so we can provide fast delivery and competitive prices, and provide reliable quality assurance within the customer’s budget. Sino-Mold is located in such an industrial advantageous town can help you finish project quick and less cost..

- Cost-effectiveness: the relatively low labor and production costs in China provide a significant cost advantage in mold manufacturing. Outsourcing to China can reduce overall mold production costs and save valuable funds for the enterprise.

- Technical expertise: China’s manufacturing technology is constantly improving, and many mold manufacturing enterprises are equipped with cutting-edge equipment and professional knowledge. Cooperation with these companies enables outsourcing partners to obtain high-quality molds and make use of China’s technical strength.

- Scale Advantage: China’s huge manufacturing scale is accompanied by abundant supply chains and resources. This accelerates mold production cycles, granting businesses greater flexibility and options.

- Specialized knowledge: Chinese mold manufacturing companies typically possess extensive experience and specialized knowledge, capable of delivering tailored solutions to meet customer demands.

- Global Support: China boasts a well-developed logistics and supply chain network, facilitating mold transportation and delivery. This helps to ensure timely deliveries and smooth implementation of production plans.

What Factors Should Be Considered When Outsourcing Mold Manufacturing to China supplier?

1.What’s supplier Reputation Like?

When exploring mold manufacturing choices for plastic business, the importance of selecting plastic product from a manufacturer with quality standards and a solid reputation cannot be overstated.

Critical elements of reputation encompass:

- Mold design

- Quality

- Timely deliveries

- Customer service

2. Is There Adequate Experience and Expertise?

Consider the supplier’s track record in molding cycle and the injection molding part making process, especially in your specific industry or product type. A supplier with relevant expertise can better understand your requirements and deliver plastic injection molds, that meet your specifications.

Choosing a mold manufacturer with mature experience can help you avoid many potential problems of molds in the future.

3. How Do They Ensure Quality?

When collaborating with a manufacturer in China, or other countries, it’s vital to confirm the presence of effective quality control protocols. This step guarantees that the products they generate align with your stringent criteria. It’s advisable to communicate with a representative from the manufacturer to acquire insights into their quality assurance processes.

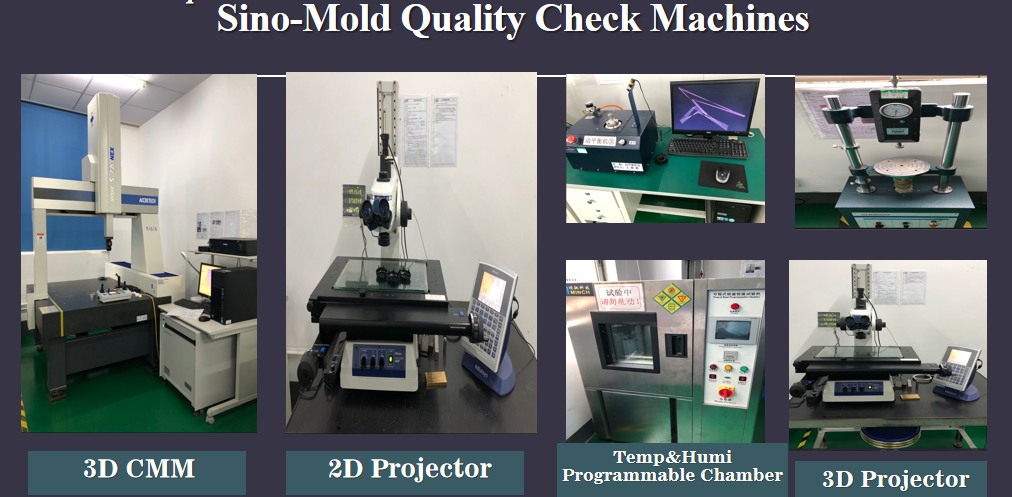

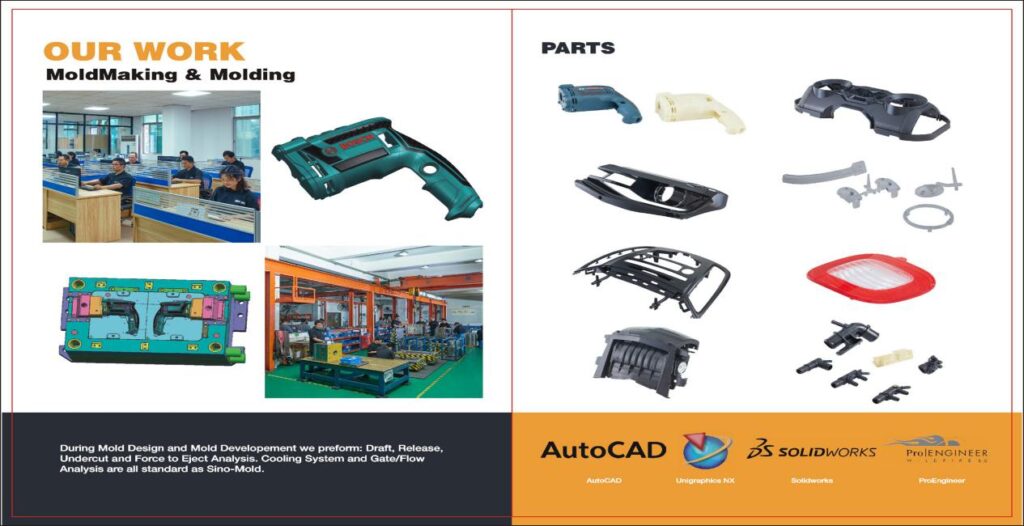

- Assessing Capability and Capacity: Examine if the factory’s capabilities and production capacity align with your needs. Inquire whether the manufacturer handles the entire production internally or outsources to multiple vendors. Verify the facility’s size and its advanced mold processing and injection molding workshops, along with testing equipment and product assembly services. Additionally, check for supplementary equipment like CNC machining, milling/grinding, engraving machines, and wire cutting, which may be essential for specific products.

- Technology and Equipment: Evaluate the supplier to manufacture your outsourcing injection mold’s technology and equipment to ensure they have up-to-date plastic injection molding machine that can handle the complexity of your outsourcing injection mold and designs.

- Flexibility and Adaptability: Ensure that the supplier is flexible and adaptable to changes, modifications, and any unforeseen challenges that may arise during the plastic injection mold making and manufacturing process.

4.How Long Does Production Take?

Lead time indicates the duration a Chinese manufacturer requires to complete your product, spanning from initiation to initial stages of completion.

This time-frame significantly influences your production timetable. Disregarding this aspect of mass production could result in extended waiting periods, with lead times potentially spanning weeks or even months for your merchandise.

5.Can Effective Communication Be Ensured?

In China, numerous other plastic injection moulding and mold manufacturers may employ sales personnel with basic English skills. However, in the realm of the plastic injection moulding and molding, profound technical comprehension and effective communication hold a significant role of paramount significance. They must grasp your product prerequisites, measurements, material specifications, and possess proficiency in CAD design and mold fabrication procedures to comprehensively fathom your requirements. The manufacturer should also proficiently elucidate the molding process, present 3D schematics, and analyze critical factor factors like size, material, and structure.

Sino-Mold’s PM is proficient in mold design and related manufacturing technology, and is fluent in English. He can have video conference with you&your customer to discuss relevant technical details on the spot, helping you communicate without barriers and complete the project smoothly and happily.

6.Can Intellectual Property Protection Be Provided?

Safeguarding your intellectual property is crucial. Are the suppliers willing to sign suitable non-disclosure agreements (NDAs) and implement measures to ensure the security of your designs and proprietary information?

From the inquiry stage to cooperate state, Sino-Mold will provide NDA to the customer. Even if the customer does not need it, we will also require internal staff to keep customer information confidential according to the NDA.

7.Is a Comprehensive Cost Analysis Available?

While cost-effectiveness is a key motivator for outsourcing to China, it’s crucial to possess a comprehensive grasp of other aspects of the overall expenses. Include not only the initial molding machine and making expense but also shipping, customs duties, potential revisions, and any other businesses concealed charges.

If customer need, Sino-Mold could offer this according to customer’s form.

8.What Does Their Shipping Policy Entail?

It’s hardly surprising that the company of shipping policy is a critical aspect that many manufacturers have to factor in while collaborating with a Chinese manufacturer company.

This pertains to the process higher cost of transporting your goods from the factory to your location. While numerous manufacturers provide complimentary shipping, it’s crucial to ensure a clear grasp of the terms and conditions linked with this provision. Failing this, unexpected shipping charges might exceed your anticipated costs.

Given the intricacies often tied to international shipping, prioritize partnering with a company committed to streamlining the process for your convenience.

9. Do They Adhere to Legal and Regulatory Compliance?

Verify if the supplier conforms to pertinent industry standards, regulations, and certifications relevant to injection molding services plastic parts, china plastic injection molding, and making.

10.What Kind of Customer Service Do They Provide?

It’s essential to evaluate the quality of customer service offered by the manufacturer. This pertains to how they handle your interactions and queries high quality products. While numerous manufacturers boast stellar customer service, seeking feedback from others remains valuable. Given the potentially long-term nature of your partnership, selecting a company you feel at ease with is of utmost importance.

- Risk Management: Have a contingency plan in place for potential issues like delays, quality concerns, or unexpected challenges that could affect the project.

- After-Sales Services:Following the export of custom molds, crucial after-sales services encompass repair and maintenance for any issues, timely supply of spare parts, ongoing technical support, opportunities for upgrades, and regular inspections. These services aim to ensure clients’ custom molds remain efficient, functional, and up to date, maximizing their long-term value and performance.

How Can You Reduce the Cost of Plastic Injection Molding components in China?

Certainly, the focal concerns of numerous mold sellers extend beyond mere quality, with cost undeniably emerging as a paramount consideration. Presented below are discreet yet invaluable insights aimed at effectively curbing the expenses associated with collaborative endeavors involving Chinese mold manufacturers.

To streamline costs related to plastic injection molding in China, the initial step entails identifying esteemed plastic and mold suppliers. Their proficiency can be harnessed to yield efficient cost savings. Prioritize vendors who furnish comprehensive quotations encompassing each stage of the process – from research and development to mold production and rigorous testing.

In the pursuit of both excellence and economical viability, seek partners who demonstrate a commitment to enhancements and wholeheartedly champion your interests. With a view to diminishing expenditures in association with your plastic injection mold supplier, deliberate upon the ensuing recommendations:

- Sample Testing: Prioritize sample testing before mass production to ensure quality. Request proofing services from mold suppliers to gauge production standards.

- Cost-Effective Design: Collaborate closely during the design phase to control costs. An experienced mold producer can optimize the design to save on overall expenses.

- One-Stop Solution: Choose one-stop injection mold suppliers for design, production, molding, and finishing services. This integrated approach enhances efficiency and reduces production time.

Partnering with knowledgeable and comprehensive suppliers allows you to streamline costs while maintaining product quality.

Conclusion

China’s injection molding sector seamlessly blends advanced technology and cost-effective solutions, guaranteeing top-tier product quality and budget efficiency. Selecting a reliable supplier of injection molded products is pivotal, with factors like cost, quality, and delivery in focus.

Effective supplier selection requires thorough research and guidance. A factory visit and relationship-building offer insights into capabilities. Establishing trust with a dependable supplier ensures ongoing confidence for your needs.

For customized injection molds, and comprehensive injection molding solutions, Sino-Mold as a reliable partner, With expertise in one-stop services, including mold design, production, and injection molding, Sino-Mold is your reliable choice. Welcome to build long-term cooperative relationship with Sino!