Custom Plastic Injection Mold Manufacturer Since 1999

SINO-MOLD delivers top-tier solutions for mold prototyping, production, and injection molding. From automotive to medical devices, consumer goods to electronics, and even die casting and various industrial sectors, our expertise ensures exceptional quality and precision for all your manufacturing needs.

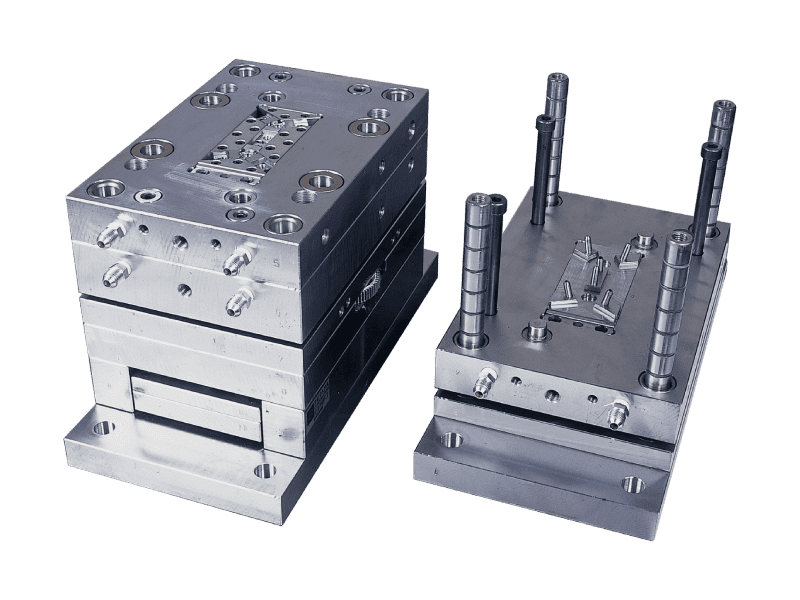

Our Creative Molding

Sino-Mold Provides Rapid Prototyping and Mass Production services for various industries, including medical devices, consumer products, automotive parts, and more.

Our Capabilities

Unique Mold Produced

Qualified Material Supplier

Company Served

Countries Exported

How Does Sino-Mold Work ?

Our experienced, English-speaking engineers collaborate closely with you to design, prototype, and perfect your custom molds, ensuring precision and quality at every step.

01 Get Your Request

Discuss your ideas with our experienced sales and engineers and receive sketches of your plans.

02 Prototyping

After confirming the 3D model, some complex products will undergo prototyping to verify assembly and function.

03 3D Modeling

At this stage,our product engineers will create a 3D model design based on your ideas.

04 Mold Design

Following prototype confirmation, our mold engineers will create a DFM report, conduct Mold Flow analysis, and design the mold.

08 Mold Assembly

Some products require assembly and packaging services according to customer requirements.

07 Post-Processing

After mass production, post-processing will be conducted including logo printing, painting, plating, laser engraving, ultrasonic welding, etc.

06 Sample Testing

After injection mold making finished, we will send the test samples to customer for comfirmation, and then start the mass production

05 Injection Mold Making

After mass production, post-processing will be conducted, including logo printing, painting, plating, laser engraving, ultrasonic welding, etc.

Why Choose Sino-Mold ?

As an ISO-certified company, we implement this standard across our production line to ensure quality control. Our rapid prototyping and batch production capabilities consistently meet our customers’ enhanced accuracy and precision demands. Our state-of-the-art factories are equipped with advanced production and measurement equipment, guaranteeing that each mold is tailored to your requirements.

25 Year Experience

Benefit from our 20+ years of experience, ensuring reliable, high-quality production with advanced equipment and a skilled professional team.

ISO 9001:2015 Certified

Our operations are ISO 9001:2015 and ISO 14001 certified, demonstrating our commitment to quality management and environmental responsibility in all our processes.

One-Stop Solutions

Streamline your product journey with our one-stop solution, integrating design to production for seamless project management, cost-efficiency, and faster turnaround under one roof.

Dedicated Team

Work with our skilled, English-certified engineers and workers who ensure clear communication and expert guidance throughout manufacturing..

Lightning Fast Delivery

Rely on our commitment to lightning-fast delivery between 7-10 days, ensuring that your urgent and planned needs are met efficiently.

24hx 7 Engineer Support

We provide round-the-clock assistance with our 7 x 24 engineer support, ensuring immediate expert help for any issues or inquiries to keep your operations running smoothly.

Our Applications

Sino-mold ensures top-notch quality across all production scales, from low-volume prototyping to large-scale manufacturing. Whether it’s high-precision aerospace assembly or producing parts for automotive and consumer goods, we employ a diverse range of materials and advanced manufacturing techniques to cater to the unique requirements of various industries.

Testimonials

Here are some cases that show how we help our customers fulfill their orders and make them happy with our products.

Our Blogs

Explore the latest industry trends and take inspiration from our updated blogs, giving you fresh insight to help Expand your Market.